Enhance Your Business Operations With Reliable Industrial Scales

In today's competitive landscape, the precision of commercial ranges plays a crucial function in boosting total business operations. Exact evaluating not only alleviates expensive inconsistencies across different sectors, such as production and logistics, but additionally ensures compliance with strict market criteria. As organizations seek to optimize effectiveness, comprehending the different kinds of scales and their technological innovations comes to be crucial. The option process can be complex, and the implications of these selections can significantly affect functional success. What variables should be considered to guarantee the ideal tools is chosen for your particular demands?

Significance of Accurate Weighing

Precise considering is vital in different industrial applications, as also small inconsistencies can lead to considerable functional inefficiencies and economic losses. Industries such as production, logistics, and food processing depend on specific dimensions to make sure item high quality, regulative compliance, and optimal resource monitoring. Incorrect weights can cause overflow, wastage of basic materials, or inadequate supply, influencing productivity and client contentment.

Additionally, accurate evaluating is vital for safety and security and environmental conformity. In the chemical sector, inaccurate dimensions can lead to incorrect blends, resulting in lawful ramifications or dangerous situations. In the food industry, precise evaluating is essential for adhering to nutritional labeling requirements, making certain that customers receive precise details regarding the products they acquire.

The integration of dependable industrial ranges not only boosts functional effectiveness but also supports data-driven decision-making. Firms that focus on accurate evaluating can optimize inventory administration, streamline supply chains, and reduce costs connected with returns and rework. Consequently, buying high-quality commercial evaluating solutions is important for businesses intending to preserve a competitive edge in today's vibrant industry. Exact evaluating eventually offers as a foundation for operational quality and lasting growth.

Types of Industrial Scales

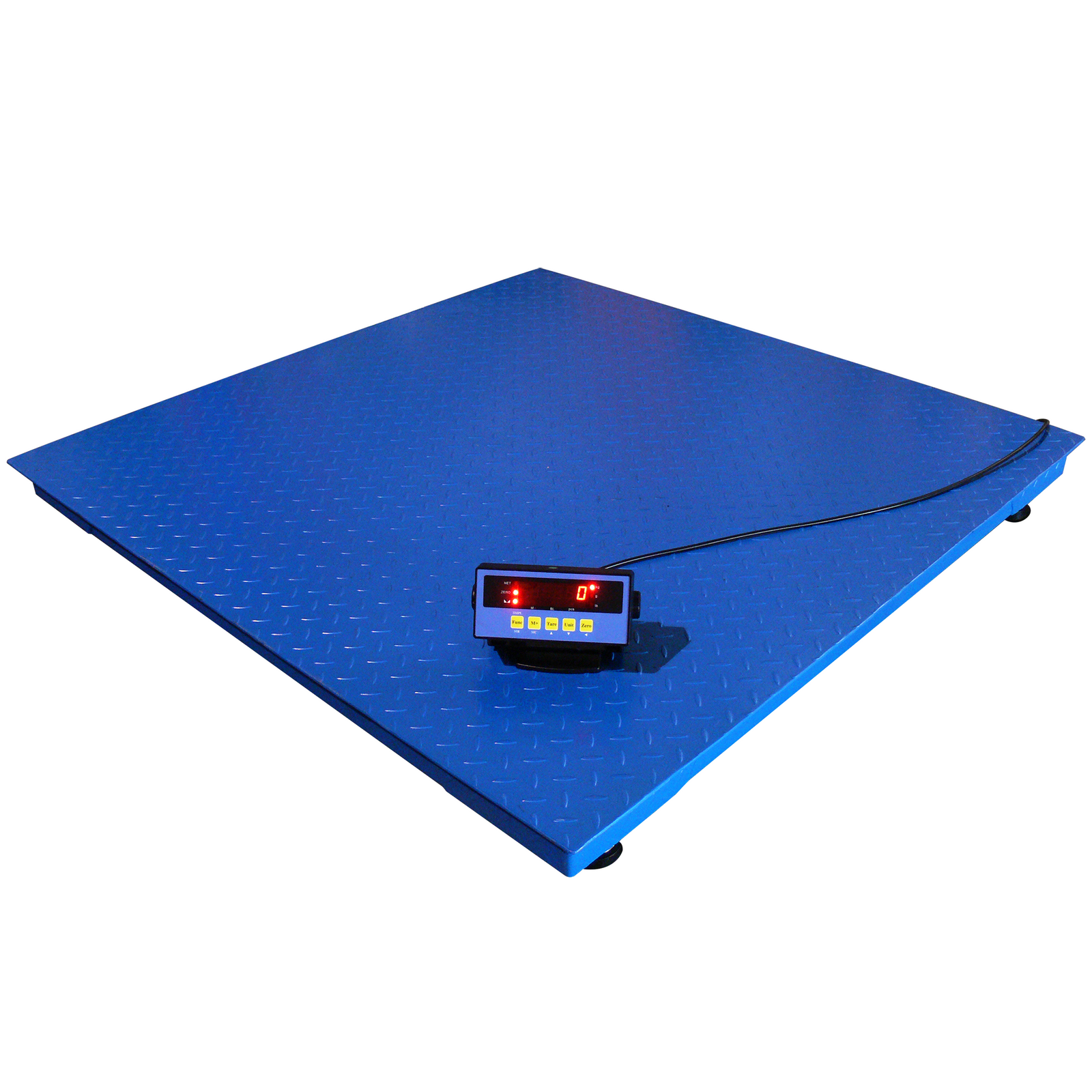

Industrial ranges can be found in various types, each made to meet certain evaluating demands throughout different markets. Among one of the most common kinds are system ranges, which supply a big weighing surface area appropriate for heavy products, making them perfect for warehouses and producing centers. These ranges usually include electronic displays for very easy analysis.

One more type is bench scales, which are generally smaller and mobile, excellent for usage in laboratories or retail settings. They permit fast measurement of smaller sized products while maintaining precision. For applications needing the weighing of fluids, tank scales are specifically designed to determine the weight of tank, guaranteeing precise supply administration.

In addition, floor scales are used for evaluating heavy loads on the ground level, often used in shipping and obtaining divisions. Crane scales are likewise significant; they are put on hold from a framework to consider hefty materials in commercial settings. Lastly, tons cells play a crucial role in numerous ranges, transforming push into an electric signal for precise weight dimension. Each sort of commercial range offers a distinct purpose, enhancing operational efficiency across diverse industries.

Benefits of Modern Innovation

Moreover, modern commercial scales typically come geared up with connection features that allow seamless assimilation with various other systems, such as stock monitoring and production monitoring. This interconnectivity promotes a much more natural process and decreases downtime, as companies can monitor performance metrics and make data-driven choices immediately.

Additionally, many contemporary scales use adjustable settings and straightforward interfaces, enabling operators to adjust their equipment for particular functional needs. Improved sturdiness and resilience against extreme ecological conditions even more add to the durability and integrity of contemporary scales, guaranteeing they can stand up to the rigors of industrial usage.

Choosing the Right Equipment

Different markets might require unique sorts of ranges, such as floor scales for heavy tons, bench ranges for smaller products, or mobile ranges for flexibility. Additionally, thinking about the atmosphere in which the ranges will be utilized is essential. Tools made use of in rough settings may need to be tough and resistant to dirt, wetness, or extreme temperatures.

An additional critical factor is the Learn More Here innovation utilized in the ranges. Digital ranges typically provide enhanced precision and simplicity of use, while analog ranges might be enough for much less demanding applications. It is important to review the scalability of the tools, making sure that it can accommodate future growth or adjustments in manufacturing processes.

Lastly, organizations should take into consideration the online reputation and dependability of producers, as investing in top quality tools can result in long-term cost financial savings and improved functional efficiency.

Maintenance for Long Life

Routine maintenance is important for ensuring the durability and optimal efficiency of commercial ranges. An organized strategy to maintenance not only expands the life of the tools yet likewise assures accurate measurements critical for operational efficiency.

Begin Clicking Here with routine assessments to recognize wear and tear, guaranteeing parts such as lots cells and displays function properly. Calibration checks must be performed on a regular basis, ideally after considerable modifications in ecological problems or adhering to heavy use. Accurate calibration is crucial for conformity with sector criteria and for keeping the reliability of weight measurements.

Cleaning is another essential facet of upkeep. Dirt, debris, and corrosive substances can hinder performance and cause errors. Usage appropriate cleaner and techniques to safeguard delicate parts. Furthermore, it is recommended to establish a maintenance schedule that records each service go to, calibration, and any repair work performed. This documentation help in monitoring devices performance and planning for future upkeep demands.

Lastly, educating staff on proper use and care techniques will certainly minimize the chance of driver error, better improving scale integrity. By focusing on routine maintenance, services can guarantee that their industrial scales remain a dependable property in their procedures.

Verdict

In summary, the assimilation of trusted industrial ranges is vital for enhancing business procedures throughout various markets. Normal maintenance and training additional add to the longevity and accuracy of these ranges, promoting data-driven decision-making and eventually supporting general company success.

Industrial scales come in various kinds, each created to satisfy particular weighing demands throughout different sectors. Crane ranges are likewise Related Site notable; they are suspended from a framework to evaluate heavy materials in commercial settings.Different sectors might need distinct kinds of ranges, such as floor ranges for hefty tons, bench scales for smaller sized things, or portable ranges for versatility - Industrial Scales. Digital scales commonly use improved accuracy and convenience of use, while analog scales may be enough for less demanding applications.In recap, the assimilation of reputable industrial ranges is crucial for improving business procedures throughout different sectors